MR®131, Magnetic Powder concentrate – Fluorescent

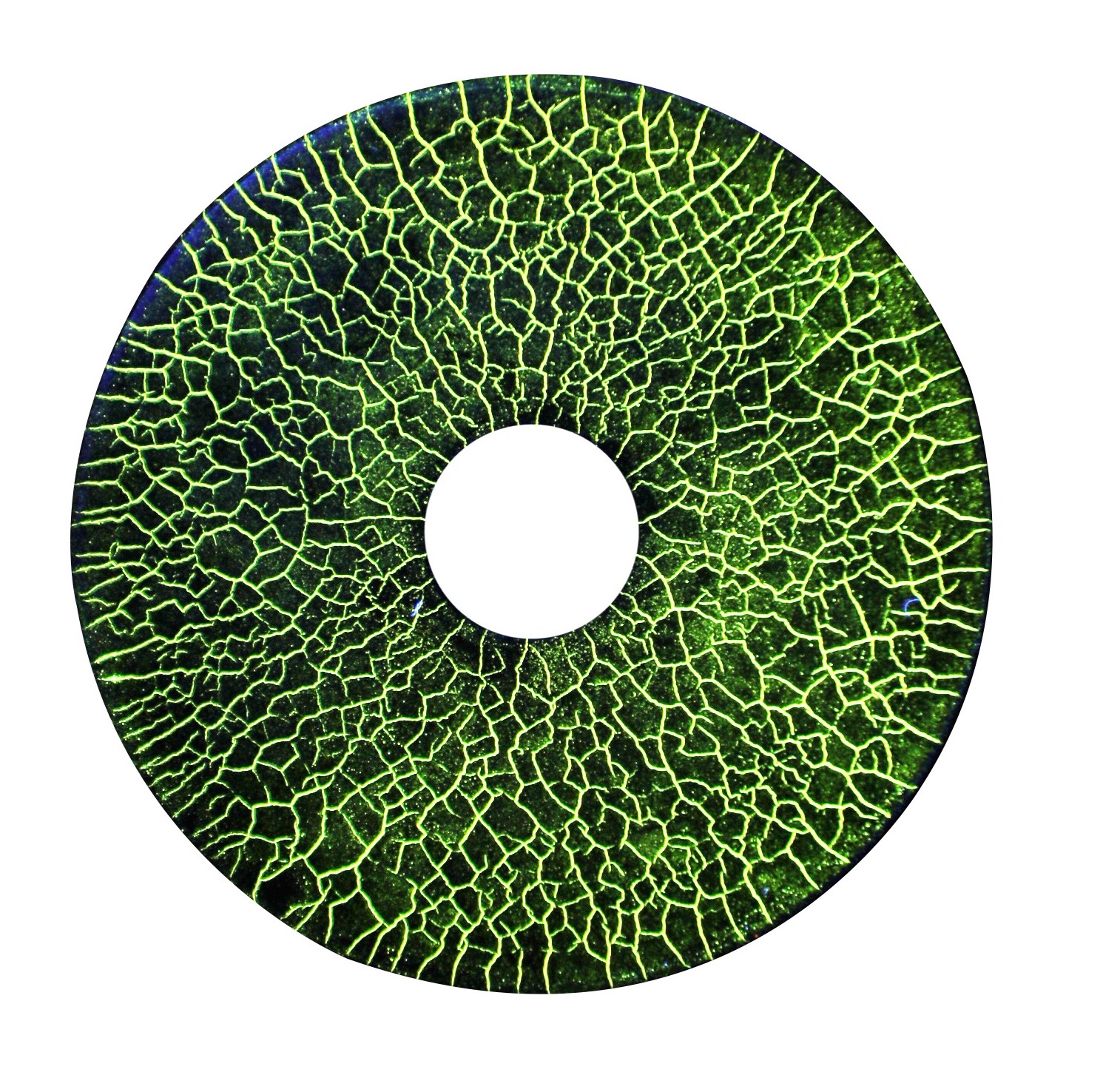

MR®131 is a bright fluorescent yellow-green (under UV) ultra high sensitive ferromagnetic liquid concentrate designed to be used with oil which is used for Magnetic Particle Testing (MPT) to locate very fine discontinuities in critical parts and applications. MR®131 particles is premixed with a special oil conditioner – including added corrosion protection and wetting agent; manufactured for an excellent particle suspension in oil, optimum sensitivity, excellent discontinuity definition, brightness with minimal to nil background and magnetic characteristics for wet method fluorescent MPT.

It detects fine to ultra fine surface and slightly sub surface discontinuities such as cracks, inclusions, seams, tears, laps, flakes and other welding defects.

| SKU | Pack Size | Case Size |

| 2511-0163 | Bulk 1L | 6 |

Additional information

| Properties | Appearance – brown liquid |

|---|---|

| Approvals | ASME Code V, Art. 7 |

| Particle Size | 1 – 3 µm * *as determined by industrial typical method for measuring particle size |

| SAE Sensitivity | 9 ** **as per indications on Ketos ring as defined in ASTM E1444/1444M |

| Sediment | 0.2 – 0.4 ml/100ml (1h) *** according to ASME ***with a dilution of 10-20 ml / L (in oil) |

| Recommended Usage | NDT Method – Magnetic Particle Testing (wet method) |

| Reference Test Blocks | Reference test block Type 1 (MTU No.3) |

Features

- Brilliant, clear yellow-green indications under UV light

- Easy to disperse in oil; no additional mixing needed

- Ultra-high brilliance

- Minimal to no background

- Optimal settling

- No odour

- Quick indications

- Long bath life

How it Works

Magnetic particle inspection (MPI) is a non-destructive testing (NDT) method used to detect surface and slightly subsurface cracks in ferromagnetic materials such as iron, steel, and nickel. The process involves magnetizing the part to be inspected and then applying appropriate magnetic particles in the form of a dry powder or suspension to the surface of the part. The magnetic particles are attracted to areas of flux leakage, which are areas where the magnetic field is distorted by the presence of a crack or other defect creating a visible indication that can be used to identify and evaluate the nature and extent of the defect.

The application of the magnetic powder creates a visible indication of the location and shape of the crack or other defect. The powder accumulates at the location of the defect, forming a visible indication or "magnetic particle indication." This indication is then examined by a trained inspector using ultraviolet light or other illumination to identify the precise location, size, and orientation of the defect.

GHS

Bulk Non Hazardous

Technology

- Protection of the core material - Encapsulation provides a protective barrier around the core material, which can help to prevent degradation or loss of magnetic activity due to exposure from carrier media - oil or water and other additives. This can extend the shelf life of the product and improve its effectiveness.

- Improved stability: Encapsulation can improve the stability of the coating material by eliminating free unbonded pigment, thereby reducing the background and enhacing the stability.

- Versatility: Our Encapsulation technology is versatile and can be used with a wide range of core materials and encapsulating materials which helps us develop various products and compatible with aqueous based, hydrocarbon based and aerosols.

- Particle Size: Our controlled spray encapsulation method and miling allows us to precisely engineer particle size and offer batch consisitency from as low as 0.2 to 75 µm.

- Particle Shape - The core material is carefully milled to a unique physical morphology of the particle that offers high mobility, attraction and retention.

FAQ

Q: What is magnetic particle inspection?

A: Magnetic particle inspection (MPI) is a non-destructive testing technique used to detect surface and slightly subsurface defects in ferromagnetic materials such as iron, nickel, and cobalt. The technique involves inducing a magnetic field in the material and then applying magnetic particles to the surface. If there is a defect present, the magnetic particles will be attracted to the defect and form a visible indication.

Q: What are the advantages of magnetic particle inspection?

A: MPI is a cost-effective, fast, and reliable technique for detecting surface and near-surface defects in ferromagnetic materials. It can be used on a wide range of materials and is relatively easy to use, making it a popular choice for many applications.

Q: What types of defects can be detected using magnetic particle inspection?

A: MPI is primarily used to detect surface and slightly subsurface defects such as cracks, seams, laps, and other discontinuities that can be detected magnetically. It is not effective for detecting internal defects such as voids or inclusions.

Q: What equipment is required for magnetic particle inspection?

A: The equipment required for MPI typically includes a magnetizing unit, magnetic particles, and a UV light source for inspecting the particles. Other equipment such as a demagnetization unit and surface preparation tools may also be required depending on the application.

Q: What are the limitations of magnetic particle inspection?

A: MPI is only effective for ferromagnetic materials, and it is not suitable for non-magnetic materials such as aluminium or copper. Additionally, the technique is only effective for detecting surface and near-surface defects, and it cannot detect internal defects. It also requires the use of a magnetic field, which may not be feasible in some situations.

Q: Is magnetic particle inspection safe?

A: MPI is generally considered safe when performed by trained professionals using appropriate safety measures. However, exposure to the magnetic field and UV light sources used in the inspection process can pose risks to those with pacemakers or other implanted medical devices, and appropriate precautions should be taken.

Q: How do I ensure that the particle concentration of a wet method product is within recommended limits?

A: In our ready to use aerosol products (MR76S (all versions), MR76F, MR76SR, MR76FR, MR76SH), the concentration of the particles will remain constant.

In our bulk versions (MR76S (all versions), MR76F, MR76SR, MR76FR, MR76SH) and bulk magnetic powders (MR111HB, MR114HB, MR110, MR158-R, MR118, MR115, MR153), the concentration of the particles will become depleted when particles are used up during the inspection process.

As such, you will need to check the bath strength at least once a day. The most widely used way of checking an ink’s settlement volume is by using a graduated ASTM pear-shaped centrifuge tube.

Q: What is the best alternative to an aerosol MPI ink that can be used in situations where flammability represents a hazard?

A: There are three options here:

- To use the bulk variant of the product (for example MR76F, MR76S are available in aerosol and bulk variants) and then apply the ink using a pump spray bottle.

- To use the water-based equivalent of the magnetic powders in aerosols.

- To use ECOLINE product versions like MR158-RGF or MR221GF

Q: Is it possible for carrier fluid to evaporate from a bath?

A: The flux oil MR82 is not very volatile and there is less chances of it getting evaporated. However, with water-based inks it is possible to see a low level of evaporation but, in this case, it is the water that is lost and not the additives such as wetting agents, defoamers and corrosion inhibitors. For this reason, if there is a need to top up a bath as a result of water loss, only water should be added, as addition of the additives could potentially cause an imbalance of the bath.

Q: What are the reasons for particle depletion when carrying out magnetic particle inspection?

A: There are a number of reasons for the depletion of particles during magnetic particle inspection, including:

Drag out of particles during the inspection process. In addition to particles being aligned around a defect, it is not uncommon to get a level of particles on the background of a component, on account of its surface roughness and geometric shape.

Over magnetisation – this can occur where a component has different thicknesses or diameters.

Particles becoming ‘stuck’ in parts of the processing equipment, such as pipework, filters, pumps etc. With this, it is not uncommon when you first fill a bath to find that you need additional particles to achieve the right settlement volume level.

The presence of contamination on a component. Contamination in the form of oils and greases, for example, could mean that particles adhere to a component as it is removed from a bath.

Q: Are water-based inks more susceptible to bath contamination?

A: There are many reasons why a bath may become contaminated. A typical example is the oil or protective coating on a component coming off in the bath due to the surfactants present within the ink. Over time, this degreasing effect can potentially lead to the build up of a ‘sludge’ of ink/oil mixture. This is less likely to occur when using an oil-based ink, as it is naturally be more able to solvate such contamination.

To overcome this problem, we recommend pre-cleaning your components using our solvent-based cleaner MR® 71 prior to carrying out inspection.

Q: Do the MR Chemie water-based ink concentrates contain wetting and antifoam agents?

A: Yes. MR® Chemie water-based ink concentrates contains wetting agents which reduces the surface tension of water and enhances particle mobility and antifoam agents to contain the foaming during the bath re-circulation.

Q: Do MR Chemie water-based ink concentrates offer corrosion protection?

A: All MR® Chemie water-based powders and liquid concentrates contain low levels of corrosion inhibitors. The level should be sufficient to give protection to parts during magnetic particle inspection testing.

Water-based inks should always be made up within stainless steel tanks

Corrosion of parts can also occur both before and after inspection so you need ensure the parts are kept clean and dry. Following inspection using water-based inks, it is especially important to ensure that any excess water is removed as quickly as possible to prevent any risk of corrosion.

If you require longer-lasting corrosion protection, treat your cleaned components with a temporary protective film coating.

Note: The duration of the corrosion protection totally depends on the type of job and working conditions along with pre and post care of the test object.

Q: How should I prepare a surface for magnetic particle inspection?

A: The surface of the part to be inspected should be free of any form of contamination that might affect the test, for example grease, water, dirt and other agents that may have been applied to the surface during the manufacturing or pre-treatment process.

Q: How do I know if my part can be tested using magnetic particle inspection?

A: A very simple way to establish if a part can be tested using magnetic particle inspection is by using a permanent magnet to see if it is ferromagnetic. If it is, the magnet will ‘stick’ to the part and you can go ahead and test it using MPI.

Q: Is Demagnetisation must after doing MPI application?

A: Demagnetization is not always a must after doing MPI application, but it is often recommended.

When a magnetic field is applied to a ferromagnetic material during MPI, it can leave a residual magnetic field in the material even after the inspection is complete. If this residual magnetism is not removed, it can cause problems in some applications, such as interfering with the operation of sensitive electronic equipment or attracting unwanted particles.

Q: Can we use the same MPI machine for WB and OB application?

A: In general, the same MPI machine can be used for both water-based and oil-based applications, as long as the machine is properly cleaned and maintained between uses. However, it is important to note that water-based and oil-based MPI applications require different types of magnetic particles. Water-based magnetic particles are designed to be dispersed in water, while oil-based magnetic particles are designed to be dispersed in oil. If the wrong type of magnetic particle is used for the application, it may not provide the desired results.

To ensure that the correct type of magnetic particle is used for each application, it is important to follow the manufacturer's recommendations for particle selection and to use separate containers and equipment for water-based and oil-based MPI applications.

Additionally, it is important to properly clean the MPI machine between uses to prevent contamination and ensure accurate results. This may involve flushing the machine with water or oil, depending on the type of application used. It is important to follow the manufacturer's recommendations for cleaning and maintenance to ensure that the machine is functioning properly and providing accurate results.

Note: MR® System Cleaner can be used for thoroughly cleaning the MPI Machine before switching from oil to water medium or vice-versa

Q: Why dark room is required while we perform MPI in fluorescent method?

A: A dark room is required while performing magnetic particle inspection (MPI) using the fluorescent method to ensure that the fluorescent particles are visible and can be accurately detected.

In the fluorescent method, a magnetic field is applied to the part being inspected, and then a solution of fluorescent magnetic particles is applied to the surface. The particles are designed to adhere to any surface or near-surface defects present in the material, creating a visible indication that can be detected using a black light or other UV light source.

To ensure that the fluorescent particles can be accurately detected, it is necessary to view the part in a dark environment. This is because the fluorescent particles emit light in the visible range when exposed to UV light, and this light can be easily overwhelmed by ambient light. By viewing the part in a dark room, the inspector can ensure that any indications produced by the fluorescent particles are clearly visible and can be accurately evaluated.

Additionally, it is important to use a dark room with controlled lighting conditions to minimize the risk of false indications. Ambient light or other sources of UV light can cause particles to fluoresce, even in the absence of defects, leading to false indications that can be misleading or difficult to interpret. A controlled environment can help to ensure that only the particles adhering to actual defects are fluorescing, providing accurate results.